MIG Welding Tips

- Jasper Jasic

- Nov 6, 2018

- 1 min read

Some quick reference handy tips for the MIG/MAG welding process are:

When welding, try to use an electrode stick out (the distance between the weld and the contact tip) of around 6-8mm.

When welding thin materials try and use smaller wire diameters and for thicker materials use thicker wires.

Make sure you select the correct wire type for the material to be welded.

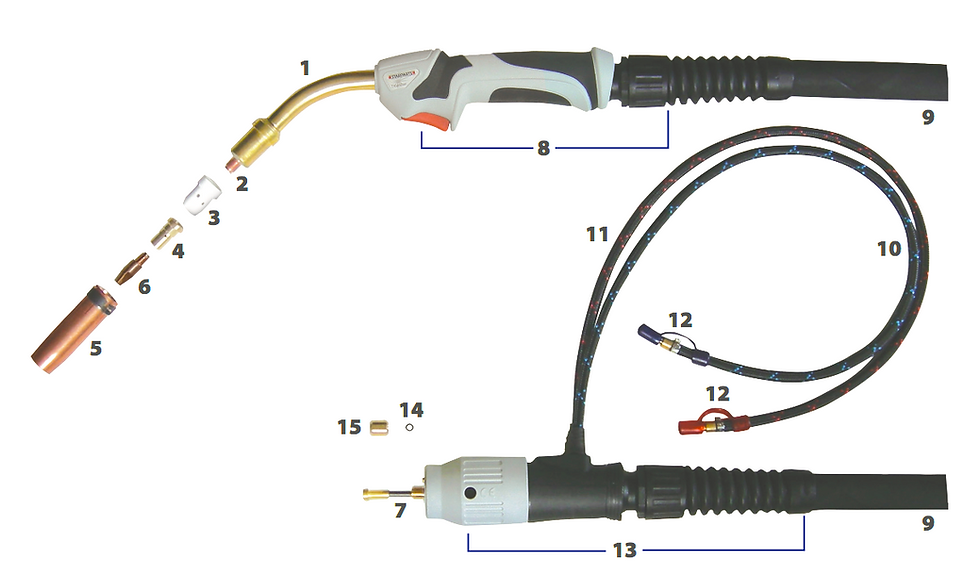

Ensure the welding gun has the correct size and type of liner.

Always ensure you have the correct size drive rolls and torch liner for the wire size selected.

Select the correct gas to achieve the correct weld characteristics and finish.

For optimum control of the weld keep the wire at the leading edge of the weld pool.

Before commencing welding, ensure a comfortable and stable position.

Try to keep the welding torch as straight as possible when welding to ensure the best feed.

Carry out daily housekeeping on the condition of the welding torch and drive rolls.

Keep any consumables clean and dry to avoid contamination such as oxidation and damp.

Comments